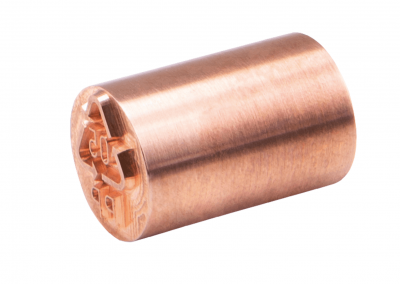

Graphite & Copper Electrode (EDM)

Advanced tools to design perfect Shaped cavities

With TYPE CAD, TYPE ART & TYPE CAM modules Tool Makers can design from any 2D curve elevation, new engraved cavities accordingly to the strict dimensions set within Blue prints. The results are way more accurate than a Solid modeller solution can bring. Vectors are perfectly defined beyog microns tolerances, and allow any element of the design to be accurately transfered to the controler of the CNC.

Electrical Discharged Manufacturing

Machines of Electro-erosion

Electro-erosion is a manufacturing process aiming to mark and engrave usually hard to cut materials mostly used in dies and molds industries. Often made of Copper or Graphite the electrode is the machined element creating the marking/engraving at a defined depth. The shape of the electrode can be as various as the design to be engraved, the first manufacturing interest being able to build squared cavities where usual rotating tooling would shape or mark falsly the area with rounded corners. Thanks to an electrical pulse built between the hard material and the power supplied electrode, the electricity replaces Tools contact by punching the material with a high voltage intensity, burning and marking the part at a defined pace insuring an end result within the mold and repeatability of the end user product built for it.

TYPE EDIT – Electrodes

Easy Profile, Easy Projection

With TYPE EDIT, build from curves 2.5D and 3D EDM Electrodes for mold and die applications. All the features needed to achieve the right result at the first time are available in TYPE EDIT and will allow you to outperform your competition.

Electrodes designed with TYPE EDIT

Want to know more about TYPE EDIT and its capabilities?

Contact us now to get in touch with a TYPE3 Representative.

Learn more about how to fulfill your customer’s designs with high level of details.