Sheets CAM Optimization

Material Management to increase Revenues

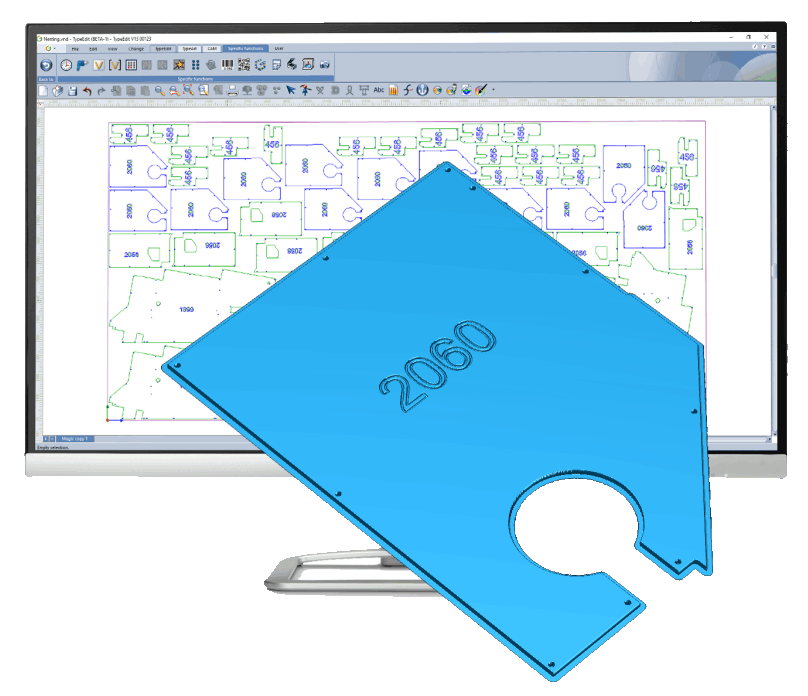

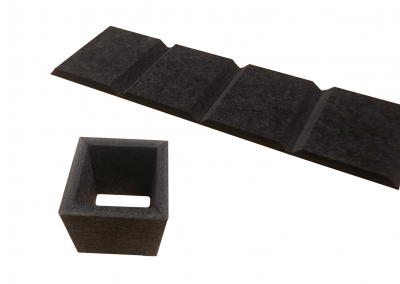

CNC Milling machines offer different bed sizes. From 4 x 8 feet long to customized sizes such as long as warehouses could be. TYPE EDIT adapts to any sheet size and with his various nesting strategies Sheets are optimized. Up to a management of uncut areas that can be stored and then reused for future jobs. Used with batch processes and the “ColorForCam” features the machining management of Sheets is as easy as building a simple 2D drawing.

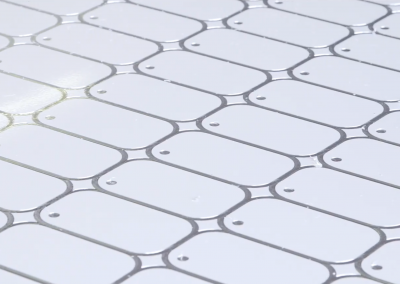

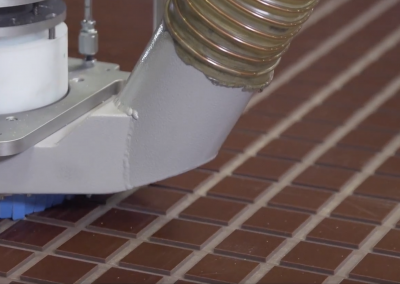

Routing

Optimization of Sheets

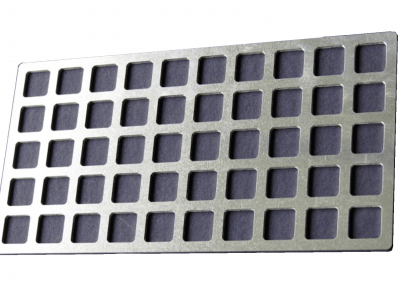

Manufacturing products from preformed and sized sheets is a process requiring a methodology not only at the time of the importation of the shapes but also all along the production with the bar codes management and the optimization of the material cut.

Tools definition with feed rate, spindle speed and lead in and lead out capabilities are important settings aiming to transform raw materials into finished products the most fastest way possible to insure returns of investment as fast. With TYPE CAD and TYPE CAM modules, Users can benefits of decades of process optimizations in the Sheet management.

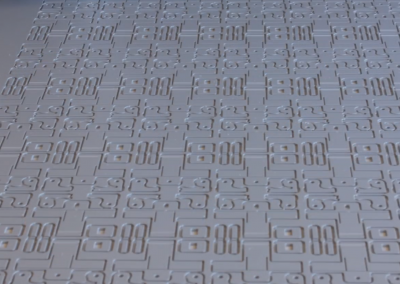

Sheet CAM Optimization

Best ROI pass through Good Optimizations

No limit to your machine neither to your sheets. TYPE CAM can nest your parts the most efficient way and save you time along the process. Insure ROI in no time by acquiring a dedicated CAD/CAM solution.

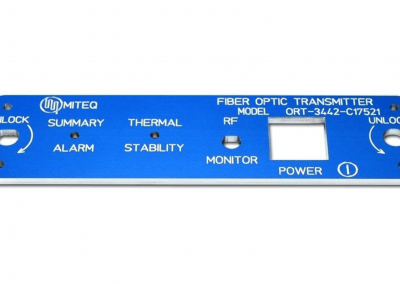

Sheet Machining set & cut with TYPE EDIT

Want to know more about TYPE CAM and its powerful toolpaths?

Contact us now to get in touch with a TYPE3 Representative.

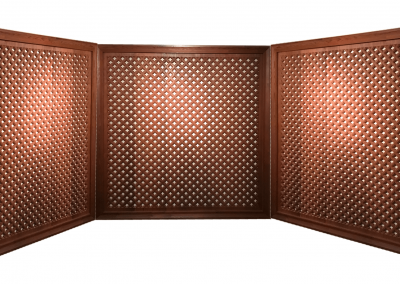

Learn more about how to fulfill your customer’s designs with high level of details.